Precision molds, professional manufacturing, we are.

Do you need a problem solver?

Hello, I’m Vivian.

Perhaps, this is the beginning of our predestined fate. You seem to be looking for a quality PET mold supplier or partner, and it is my pleasure to assist you with any challenges you may have. Allow me to briefly introduce:

Position: I am the second-generation owner of Zhongshan Jindong Machinery Co., Ltd. (my father founded this factory in 2004), and I am also the founder of www.vivianmold.com and www.ibottler.com.

Personality: Loyal, responsible, professional, both inner beauty and outer elegance, truly embracing the joy of life.

Family status: I am happily married with two lovely sons.

Pros: With 14 years of experience in plastic bottle machinery and molds, I approach my work with unwavering diligence and meticulous attention to detail, I reach out even beyond the reach of my client base Scope, it gives me great satisfaction to help those who solve the blow molding machine dilemma.

Cons: While my spoken English might be considered average due to my academic background in business administration, rest assured this in no way diminishes my expertise in the blow mold and preform mold industry.

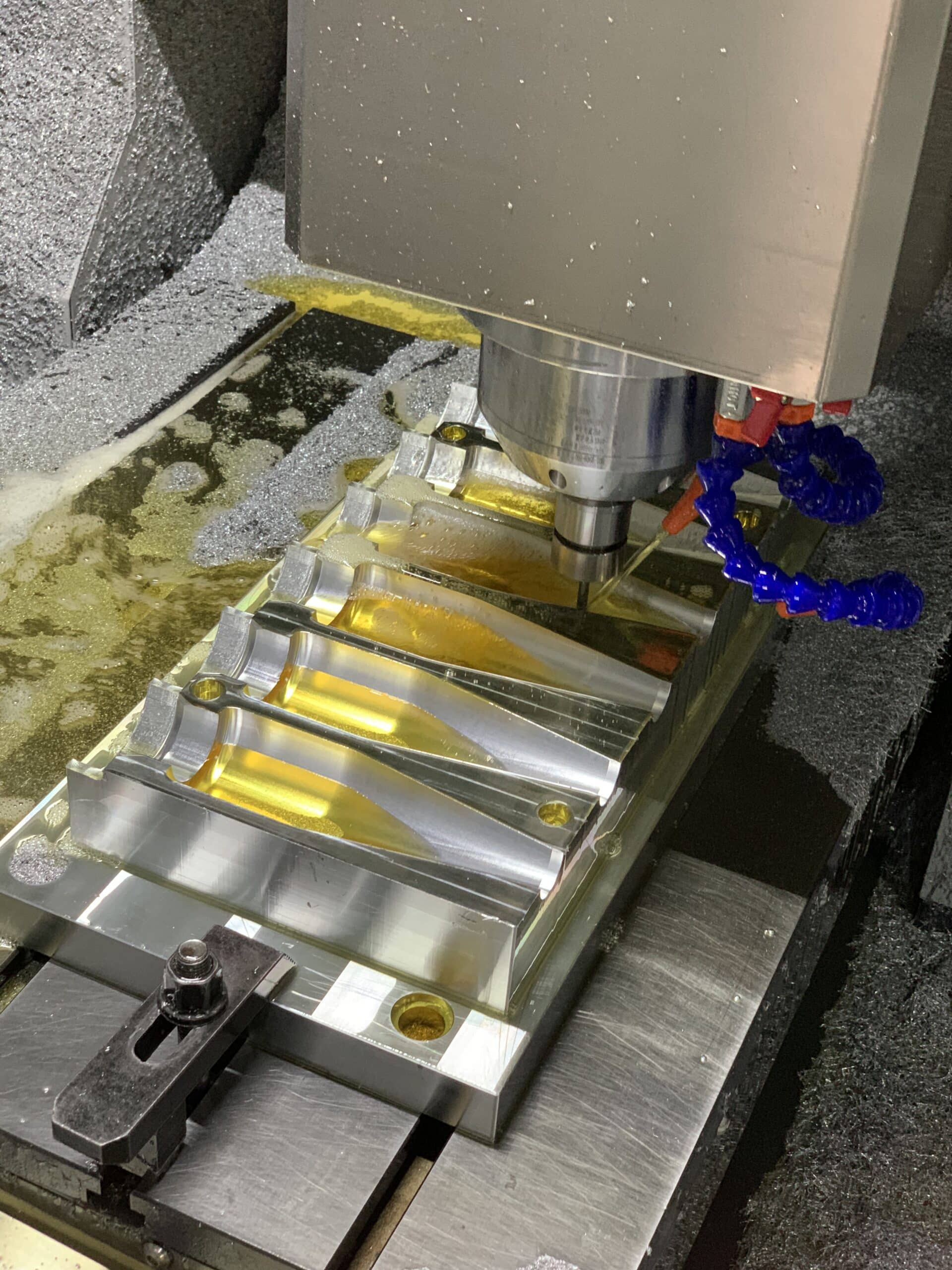

Mission: My core desire is to manufacture high precision, durable and competitively priced PET molds. By simplifying the complexity of PET bottle molds, the molds are easier to install and produce, and last longer.

Through my blog I will address common issues and present real case studies encountered in the production of plastic bottles. My ultimate goal is to provide effective solutions and rich professional insights to my peers.

If you have any questions, please feel free to contact me, let’s discuss and learn together, let’s embark on this meaningful journey together!

Connect

- +861306288777

- +861306288777

- Vivian Hsu

In production, do you encounter the following problems?

-

The bottom of the PET preform is whitish? 01

Reason 1. Insufficient temperature of hot runner 2. Insufficient material temperature. Elimination method: 1. Strengthen heat insulation measures 2 . Increase the temperature of the nozzle here 3 . Properly increase the material temperature 4. Speed up the injection speed5. Reduce the holding pressure6. slow down cooling water flow.

-

PET preforms are opaque? 02

Reason: 1. Insufficient drying of raw materials 2. Insufficient plasticization of raw materials 3. pp> preform wall thickness is too large or insufficient cooling 4. mixed with other plastics 5. Material temperature is too low. Elimination method: 1 Guaranteed to dry for more than four hours 2. Raise the material temperature 3. Increase the screw speed 4. Check whether the temperature of the drying material is too low or the injection volume does not match. It is necessary to ensure that the raw material is dried at 165 degrees until the moisture content is less than 0.02%. 5. Enhanced cooling, thinner wall thickness.

-

PET preforms have air bubbles? 03

Reason: Insufficient drying. Elimination method: 1. Strengthen drying 2. Increase material temperature 3. Reduce screw speed.

-

There is fog on one side of the PET preform? 04

Reason: 1. Holding pressure too high 2. Bottom film gate hole eccentric. Elimination method: 1. reduce stress 2. Correction mold.

-

Depression on the PET preform surface? 05

Reason: 1. Material temperature is too high 2. injection rate is too short 3. Dwell too short 4. Injection time is too short 5. Insufficient cooling. Elimination method: 1. Lower material temperature 2. Reduce the injection rate 3. increase pressure 4. increase injection time 5. increase water pressure.

-

Uneven PET preforms? 06

Reason: 1. Poor mold manufacturing 2. Gate hole deviation 3. Injection pressure too high 4. core shift. Elimination method: 1. Correction mold 2. Raise material temperature 3. turn down the pressure 4. Mold with high strength, high precision and adjustable core structure.

-

Bending of PET preform after demoulding? 07

Reason: 1. Gate hole eccentric 2. uneven cooling. Elimination method: 1. Correct mold 2. Reduce the holding pressure 3. Increase injection speed 4. extended cooling 5. Clean up waterways 6. Increase cooling water pressure.

-

PET bottle whitish? 08

Reason: 1. The heating temperature is too low. 2. The wall thickness of the embryo tube is uneven. 3. The thickness of the embryo tube is too thick, and the heating penetration is insufficient. Elimination method: 1. Raise the temperature or slow down the revolution speed 2. Improve the quality of the embryo tube 3. Reduce the thickness of the preform, or try to increase the outer cover of the heating device to increase the temperature distribution of the preform surface

-

Uneven wall thickness of PET bottle? 09

Reason: 1. The position of the stretching rod is not in the center of the embryo tube. 2. The blowing hole is asymmetrical and the hole diameter is different. 3. The stretching ratio is too low or the inflation ratio is too small. 4. The embryo tube does not rotate in the heating furnace. 5. The wall thickness of the embryo tube is not good. Uniform or uneven injection density. Elimination method: 1. Adjust the position of the stretching rod 2. Adjust the position and diameter of the blowing hole 3. Increase the stretching ratio or inflation ratio 4. Check the rotation device 5. Improve the quality of the preform.

-

Bottle parting line thickness? 10

Reason: 1. Mold clamping pressure is not enough 2. Sealing time is too early 3. Mold problem 4. The size of the embryo tube mouth does not match the mold. Elimination method: 1. Increase the mold clamping pressure, adjust the angle of the mold clamping strut (<5 degrees) 2. Move the position of the mold clamping travel switch backward 3. Repair the mold or check the mold assembly position, such as whether the guide post is loose or whether the mold is not Compression 4. Repair the matching position of the teeth of the mold.

-

PET bottle bottom blasting? 11

Reason: 1. Delayed air blowing time is too short 2. Delayed mold opening time is too short 3. Temperature is too high 4. Exhaust valve does not work. Elimination method: 1. Extend the delayed air blowing time or increase the descending speed of the stretch rod 2. Extend the delayed mold opening time 3. Cool down 4. Clean the exhaust valve with gasoline.

-

PET bottle transparency is not good? 12

Reason: 1. The heating temperature is too high. 2. The heating time is too long. 3. The compressed air contains moisture. 4. The embryo tube itself is opaque. 5. The embryo tube design is not suitable. 6. The inflation ratio is too small. Elimination method: 1. Lower the temperature 2. Shorten the heating time 3. Use a dryer to remove water 4. Improve the quality of the embryo tube, select materials and increase the dryness of the raw material 5. Improve the size design of the embryo tube 6. Reduce the diameter of preform.

Technical Discussion and Analysis of Mold Industry

How to Choose the Right Blowing Mold Manufacturer?

Beginner’s Guide: How to operate the blowing mold ?

Five Common Misunderstandings in Blow Mold Purchasing

Are you wondering about the future of soda?

Nigerian Mineral Water Market Analysis

Choose a plastic bottle or a glass bottle?

Brief Analysis of Orange Juice Beverage Market

Classification and Importance of Tags

What Factors Should Be Considered In Designing Bottles?

Can a good bottle design increase sales?

Author: Vivian

Motto: Only those who can do every little thing well can accomplish great things.

my latest articles

Fill out the form to get the mold price

Take a minute to fill out the form and you can get a free design.

Tell Us What You Need

Try to tell me your requirements, such as the capacity of the bottle, the output you want, or the problem you are encountering now.

Get Solution & Quote

We will provide customized solutions for bottle blowing molds according to your requirements.

custom production

Bottles are designed according to your detailed needs and custom produced.