**Outline:**

1. **Introduction**

1. Overview of the bottle mold industry

2. Importance of making informed decisions in procurement

2. **Common Misconceptions in Blowing Mold Procurement**

1. Assuming all molds are the same

2. Ignoring the material composition

3. Overlooking maintenance requirements

4. Neglecting the supplier’s reputation

5. Prioritizing cost over quality

3. **How to Avoid These Pitfalls**

1. Recognizing the diversity of molds

2. Researching on material advantages

3. Regular maintenance checks

4. Vetting suppliers

5. Balancing cost and quality

4. **Why Experience Matters**

1. The advantage of seasoned manufacturers

2. Navigating industry challenges with experience

5. **Choosing the Right Partner: Zhongshan Jindong Machinery Co., Ltd.**

1. A look into the company’s history

2. Commitment to quality and service

6. **Conclusion**

7. **FAQs**

**Introduction to the Bottle Mold Industry in China**

01. Blowing mold industry introduction

The plastic bottle industry, closely interwoven with the bottle mold sector, has seen phenomenal growth over the past few decades. China, a powerhouse in global manufacturing, is at the heart of this development. This introduction will dive into the nuances of the bottle mold industry in China, emphasizing the importance of making informed decisions during procurement.

**Overview of the Bottle Mold Industry**

China’s rapid industrial growth, fueled by advancements in technology, infrastructure, and labor force, has transformed it into the world’s factory. One of the pivotal sectors underpinning this growth is the bottle mold industry.

In the context of the bottle mold sector, China is more than just a large-scale producer. The nation has managed to combine the traditional craftsmanship with modern manufacturing techniques, making it a beacon for innovation and quality. With a history stretching back to the 1990s, China’s bottle mold industry has evolved from basic production to sophisticated designs, accommodating various materials and catering to diverse market demands.

The proliferation of this industry can be attributed to a few critical factors:

1. **Economies of Scale:** China’s vast manufacturing base allows for mass production, which in turn, results in cost reductions.

2. **Innovation and R&D:** Chinese manufacturers invest heavily in research and development, leading to the creation of state-of-the-art molds that cater to diverse requirements.

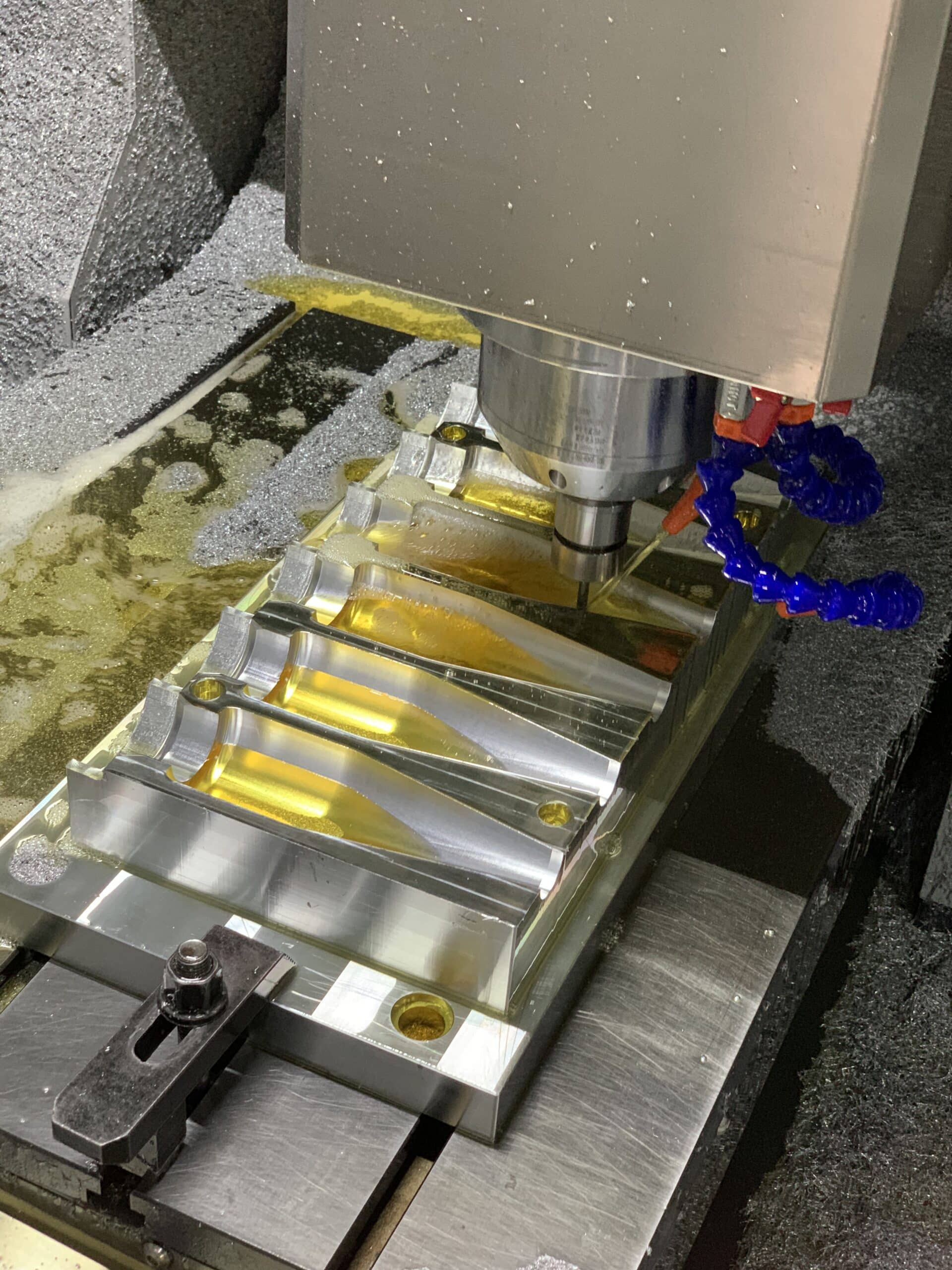

3. **Integration of Technology:** The incorporation of advanced machinery and automation has elevated the precision and efficiency of mold production.

4. **Skilled Labor Force:** With a blend of experienced artisans and a younger, tech-savvy workforce, China offers a unique mix of expertise in mold crafting.

**Importance of Making Informed Decisions in Procurement**

With a plethora of options available, procurement in the bottle mold sector can seem overwhelming. However, informed decision-making becomes crucial for several reasons:

1. **Quality Assurance:** The vast number of manufacturers implies varying quality standards. Ensuring that the procured molds adhere to international quality benchmarks is paramount.

2. **Cost Implications:** While China offers competitive prices, focusing solely on cost can lead to procurement of sub-par molds, which may entail higher long-term expenses due to replacements or defects.

3. **Vendor Reliability:** As the industry is dense, understanding the reputation and credibility of the manufacturer is essential. Partnering with a reliable vendor ensures timely deliveries, adherence to agreements, and post-sales support.

4. **Customization:** Different markets have unique demands. Collaborating with a manufacturer who understands and caters to specific requirements ensures that the end product aligns with market needs.

02. Five Common Misunderstandings in Blow Mold Purchasing

1. **Do you want to make the bottle blowing mold first and then find the bottle blowing machine? **

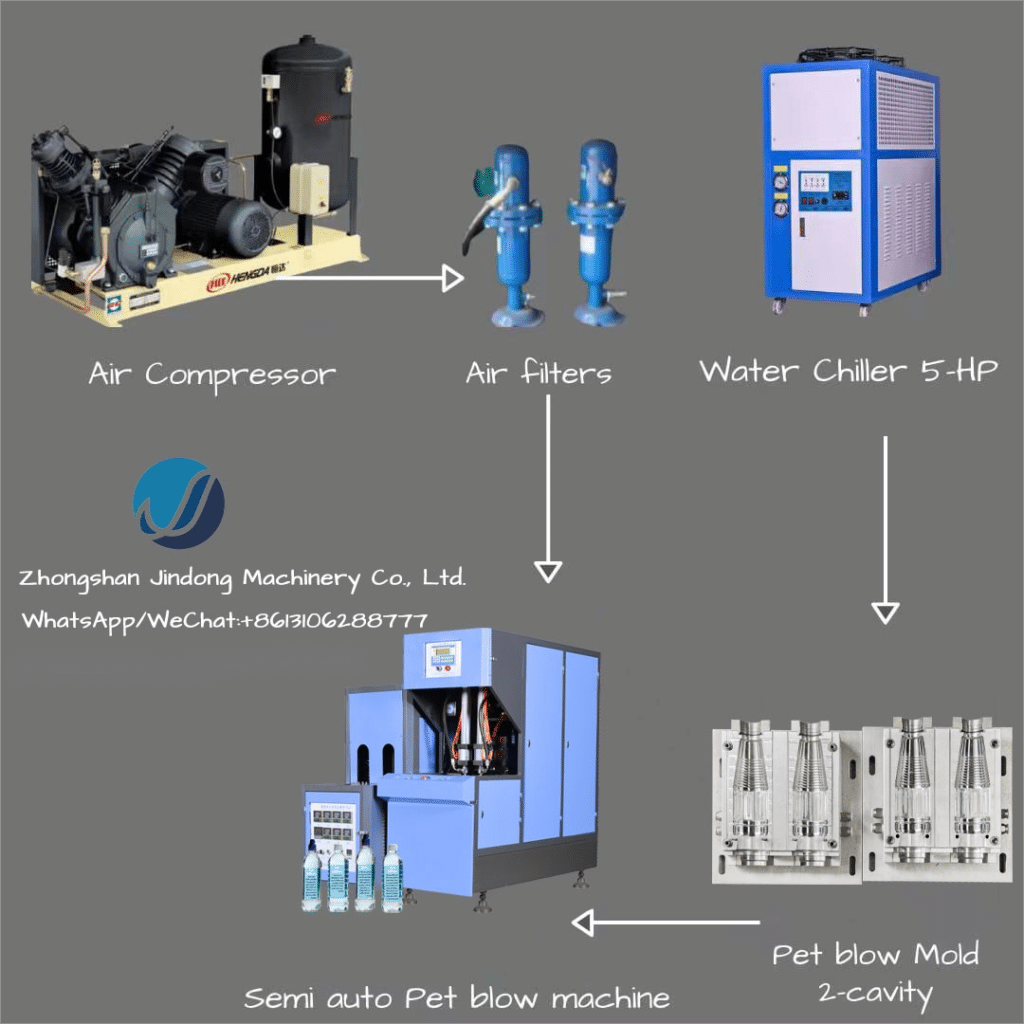

I met a lot of novice customers, the first time I came into contact with this industry, and wanted to produce plastic bottles. When they asked me to make molds, the first thing was to quote. I will patiently explain that the blow molding mold can only be produced with the blow molding machine. I need to know the type of your blow molding machine, semi-automatic or fully automatic blow molding machine. They often say, I don’t have a blow molding machine, I just need a blow molding mold. In fact, they don’t know that the production of plastic bottles needs to be combined with blow molding machines, molds, air compressors and other auxiliary machines to produce them. The bottle blowing mold is made according to the type of your bottle blowing machine, because the structure of the bottle mold is different for different bottle blowing machines, so if you want to make a set of bottle blowing molds, you must first make sure that your production The blow molding machine for this blow molding mold, because we must ensure that the blow molding mold and the blow molding machine are matched to produce, so first determine the blow molding machine and then make the blow molding mould. If you have enough funds, you can purchase all blow molding machine mold air compressors. If you are short of funds now, you can find your local factory, a plastic bottle factory with blow molding machines, to help you produce and produce plastic bottles. You only need Just make 1 set of molds.

2. **Is the material of the blowing mold not important? **

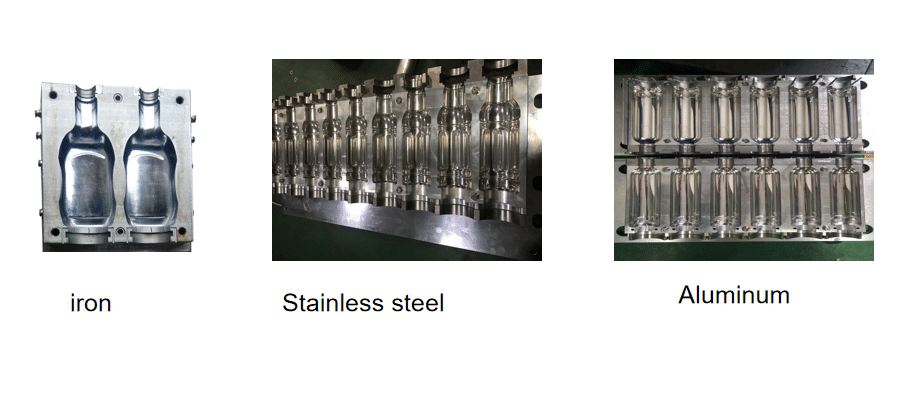

There are three main materials for bottle blowing molds: iron, stainless steel, and aluminum.

From 1995 to 2005, when the plastic bottle industry was just emerging in China, most of the factories chose iron material for the manufacture of blowing molds, because the iron material is cheap, the material hardness is high, and the iron surface is electroplated, which can ensure a The mold will not rust for about a year, even if it is rusted, it can be re-plated and reused. However, as the plastic bottle industry has higher and higher requirements for products, the method of iron material plus electroplating has gradually begun to be eliminated. 1. The electroplated mold is easy to rust, and the cost of re-plating will increase. 2. The surface finish of the iron mold is not high, and the finished plastic bottle is not perfect. Of course, there are still customers who want to save costs and choose iron molds, but they ignore the service life of the molds. If there is no electroplating factory in your local area, the service life of your iron molds is only 1 year, which actually increases the cost.

Most of the daily chemical bottle molds are now made of stainless steel, because during the production of cosmetic bottles, the mold is easy to swell. The hardness of stainless steel can solve this problem very well, and the mold of high-temperature filling beverage bottles is also an option. Made of stainless steel.

Aluminum material is currently the choice of most bottle blowing moulds. Aluminum material is light, and it is a great advantage to replace the mold. Taking a 500ML bottle blowing mold with 6 cavities as an example, the stainless steel mold is about 180-200KG, but the aluminum material The mold is about 80-100KG. For stainless steel molds, it is difficult for two people to complete the mold replacement within half an hour, but for aluminum molds, two workers can easily complete the mold replacement within half an hour. Also, due to the high hardness and heavy material of the stainless steel mold, the impact on the mold frame of the blow molding machine is relatively strong, which may aggravate the damage of the blow molding machine.

So when you choose the material of blow molding mold, you should not only consider reducing the cost, but consider the plastic bottles you produce comprehensively and combine your blow molding machine to choose the most suitable blow molding mold for you.

3. **Ignoring Maintenance Requirements**

In my return visits to many customers, I have come to the conclusion that most users shorten the service life of the mold because they do not pay attention to the maintenance of the blowing mold. A set of high-quality bottle blowing mould, as long as it is maintained regularly, has a service life of at least 5 years. But why do many customers’ molds have various problems after being used for 1-2 years? Because workers neglect regular maintenance during mold production.

A. During the production of the blowing mold, because the air compressor supplies air and the chiller cools the mold, there will be a temperature difference, and some small water droplets will appear on the surface of the mold. If these water droplets are not cleaned in time, after a long time, even aluminum The material will also oxidize, and white aluminum oxide will form on the surface, so that the surface of the plastic bottle produced in this way is no longer smooth and transparent, but blurry. Therefore, if the mold has water droplets or accidentally touches water, it must be wiped in time.

B. The bottle blowing mold is not in production, how should we maintain it? If the blow molding mold is not in production, whether it is installed in the blow molding machine or stored in the warehouse, we must keep the environment dry and free from wet water. Furthermore, we need to spray a layer of anti-rust oil on the surface of the blowing mold, and then wipe the anti-rust oil when it is produced again.

C. According to the actual production situation, the surface of the mold is polished every year or two, and the water is cleaned and transported. Regular warranty, the mold after polishing is like a new mold, which greatly increases the service life of the blowing mold.

4. **Ignoring Supplier Reputation*

As a big plastic country, China’s plastic machinery and mold industries account for a large proportion of the world. It is undeniable that there are many excellent mold suppliers in China, but there are also some dishonest factories.

I have a mold from a South African customer. When he sent me a photo of the mold, I was actually quite shocked. This bottle blowing mold does not carry water, (because the mold must have a water channel, which is connected to a chiller, and the circulating cooling water can keep the mold from heating up during production and maintain continuous production), and it is made of iron, and the mold Has been heavily rusted. According to my preliminary understanding, the price purchased by customers is not low. He wants to buy a blow molding machine with me now, but wants to use this mold back. It took me a long time to explain that this mold cannot actually be produced, because once the mold gets hot, the bottle will be deformed and a qualified plastic bottle cannot be produced. The customer couldn’t understand and always thought that I wanted him to purchase a new mold. He found a mold factory again and purchased a blow molding machine. A year later, he contacted me again, looking for me to re-make molds and buy blow molding machines. He said that he had spent money to buy a lesson.

So when you are looking for suppliers in China, you must look for a high-quality factory, not a trading company. The factory must have its own production workshop and be able to contact the most important person in charge, or you can first understand the industry and accumulate a certain amount of experience. Knowledge repurchases.

5. **Cost priority over quality? **

Whether it is a buyer or a manufacturer, the only thing they care about when making molds must be the price, there is no doubt about this. But either the price is low, or the cost is reduced? the answer is negative. Just like my customer in South Africa, he actually bought an extra set of equipment, and the final cost doubled. There are many such cases among the customers I have contacted. They all choose low-priced blow molding molds, but spend more money to make up. Therefore, when choosing a mold factory, when choosing a product quotation, you should not only focus on low prices. I am a customer from Kenya, I quoted the price of the mold, he said it was too high, and then he took a screenshot of the quotation and gave me the price of the mold from another manufacturer, if it is a real aviation aluminum material, including the material fee Neither is enough. I didn’t refute with the customer, I just explained the real material price of aviation aluminum to the customer. Based on his 500ML mold, the material price I got theoretically is already higher than the price of this mold.

To sum up the above, in the first step of buying a blow molding mold, you must first determine your blow molding machine, and then choose the material of the mold according to your own funds and the needs of the plastic bottle, and then when looking for a supplier, you must comprehensively Consider and choose a high-quality and reliable supplier. A good supplier can save your cost. After receiving the mold, you must tell the workers to do regular maintenance and maintenance.

03.How to Avoid Pitfalls in the Bottle Mold Industry

The bottle mold industry, especially within China’s expansive manufacturing landscape, presents opportunities alongside challenges. The pitfalls can result in subpar products, increased costs, and disruptions in supply chains. Here’s a comprehensive guide on avoiding these pitfalls:

1. **Recognizing the Diversity of Molds**

– **Description:** Molds vary widely, from their design, size, and material, catering to different production needs. Not all molds are suitable for every application.

– **Solution:**

* Conduct a thorough needs assessment to identify the specific mold type required for a particular application.

* Familiarize oneself with different mold designs and their respective applications to ensure that the chosen mold aligns with the production objectives.

2. **Researching on Material Advantages**

– **Description:** The material from which the mold is made can significantly influence its performance, longevity, and the quality of the finished bottle.

– **Solution:**

* Understand the characteristics of various mold materials, such as their resistance to wear, heat transfer capabilities, and durability.

* Depending on the intended use, choose materials that align with the requirements. For instance, for high-speed production, a material with excellent heat transfer properties might be ideal.

3. **Regular Maintenance Checks**

– **Description:** Like any tool, molds suffer from wear and tear. Ignoring regular maintenance can reduce mold life and negatively impact bottle quality.

– **Solution:**

* Establish a routine maintenance schedule to inspect molds for signs of wear or damage.

* Employ technicians trained in mold maintenance. They can identify potential problems early, ensuring that minor issues don’t escalate into significant disruptions.

* Keep records of maintenance activities to forecast when a mold might need replacement or significant repairs.

4. **Vetting Suppliers**

– **Description:** With a myriad of suppliers in the market, there’s a risk of partnering with unreliable or inexperienced ones.

– **Solution:**

* Conduct comprehensive background checks on potential suppliers. This should include checking references, reading reviews, and even visiting their manufacturing facilities if possible.

* Engage in trial runs or pilot projects with a new supplier before committing to a large-scale collaboration.

* Seek recommendations from industry peers or join industry associations, as they often have insights into reputable suppliers.

5. **Balancing Cost and Quality**

– **Description:** While seeking cost-effective solutions is essential, focusing solely on price can lead to acquiring inferior quality molds.

– **Solution:**

* Understand that a higher initial investment in a quality mold can result in long-term savings due to reduced maintenance costs, longer mold life, and better product output.

* Instead of just comparing prices, evaluate the total cost of ownership, which includes not only the initial purchase price but also maintenance costs, expected lifespan, and the potential cost of defects or disruptions.

* Collaborate with suppliers who have a track record of providing good quality at competitive prices, ensuring you don’t compromise on either aspect.

**Conclusion**

Successfully navigating the complexities of the bottle mold industry requires a combination of knowledge, vigilance, and strategic planning. By recognizing the potential pitfalls and implementing the aforementioned solutions, businesses can ensure they maximize the benefits while minimizing risks in this dynamic sector.

04. Why Experience Matters

In any industry, and particularly in manufacturing, experience is the cornerstone upon which reliability and excellence are built. This is true for the bottle mold sector as well.

1. **The Advantage of Seasoned Manufacturers**

– **Depth of Knowledge:** Experienced manufacturers have a well-rounded understanding of the nuances of the bottle mold industry. They have seen the evolution of materials, techniques, and market demands.

– **Reduced Lead Times:** A seasoned manufacturer often has streamlined processes in place, ensuring faster turnaround times without compromising on quality.

– **Risk Management:** With experience comes the ability to anticipate potential pitfalls and challenges, and more importantly, to have strategies in place to address them.

2. **Navigating Industry Challenges with Experience**

– **Evolving with Trends:** Experienced players have a history of adapting to new market trends and requirements, ensuring they remain relevant and competitive.

– **Solving Unforeseen Challenges:** When unexpected issues arise, whether they are design challenges or supply chain disruptions, seasoned manufacturers can leverage their past experiences to find solutions more rapidly.

– **Maintaining Client Relationships:** An experienced manufacturer knows the importance of nurturing long-term partnerships with clients, fostering trust and reliability.

O5. Choosing the Right Partner: Zhongshan Jindong Machinery Co., Ltd.

Selecting the right manufacturing partner can make all the difference in ensuring product quality, reliability, and business growth.

1. **A Look into the Company’s History**

– Founded decades ago, Zhongshan Jindong Machinery Co., Ltd. has steadily risen to be a dominant player in the bottle mold industry. Their journey is marked by continuous innovation, adaptation, and a commitment to excellence.

2. **Commitment to Quality and Service**

– **Unwavering Quality Standards:** The company prides itself on its rigorous quality control measures, ensuring every mold produced meets international standards.

– **Client-Centric Approach:** Zhongshan Jindong Machinery Co., Ltd. understands that every client has unique needs. Their team collaborates closely with clients to tailor solutions that fit specific requirements.

– **Continuous Training:** The company invests in regular training for its workforce, ensuring they remain updated with the latest industry advancements.

06. Conclusion

The bottle mold industry is rife with challenges and opportunities. With the right partner, like Zhongshan Jindong Machinery Co., Ltd., businesses can navigate this landscape with confidence. Their blend of experience, commitment to quality, and client-centric approach makes them an invaluable ally in the manufacturing world.

07. FAQs

– **Q: How often should bottle molds be replaced?**

– A: The lifespan of a bottle mold depends on its material, usage frequency, and maintenance. Regular checks will provide insights into its condition.

– **Q: How do industry trends influence mold designs?**

– A: As consumer preferences evolve, so do mold designs. For example, eco-friendly materials and innovative bottle shapes may drive changes in mold designs.

– **Q: Why is Zhongshan Jindong Machinery Co., Ltd. a preferred partner for many businesses?**

– A: Their decades-long experience, coupled with a steadfast commitment to quality and client satisfaction, makes them a trusted choice for many.