Professional bottle design is better than advertising

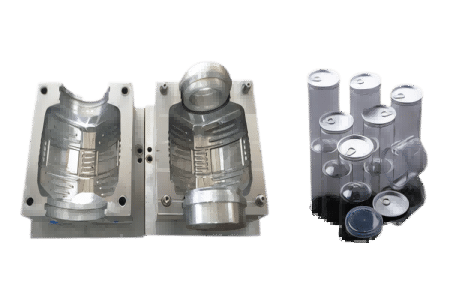

Blowing mold

- Experience precision, quality and innovation.

water bottle mold

Molds for semi-automatic and fully automatic blow molding machines,The mold has a high finish and is more durable.

Daily chemical bottle mold

SIDEL, SIPA, Krones, SACMI and other blow-fill-rotary-blow molding machines matching molds.

Oil bottle mold

10-20L Non-recyclable Big Bucket Water, Disposable Recyclable Big Bucket Water Mold.

Wide Mouth Jar Mold

Molds for semi-automatic and fully automatic blow molding machines,The mold has a high finish and is more durable.

Soy sauce bottle mold

SIDEL, SIPA, Krones, SACMI and other blow-fill-rotary-blow molding machines matching molds.

18.9L bottle mold

10-20L Non-recyclable Big Bucket Water, Disposable Recyclable Big Bucket Water Mold.

Our advantage

- Free design, custom production

- All processed by CNC lathe

- 20+ Blow molding experience

- High-quality cooling channels

- Mold life "6 million times"

design team

With a research and development team of 15 people, the bottle designer has more than 10 years of experience in the design and assembly of blowing molds and preform molds.

Sample room

Our factory has a sample inspection room of 300 square meters, and more than 3000 bottles of samples are used for sample inspection and preservation.

Processing Equipment

There are more than 30 sets of CNC machining centers, large milling machines and CNC lathes, more than 10sets of professional machinery such as pressure-resistant instruments for bottles and leak-testing instruments.

Send order now, free design

Our order process

- It's easy to place an order with us

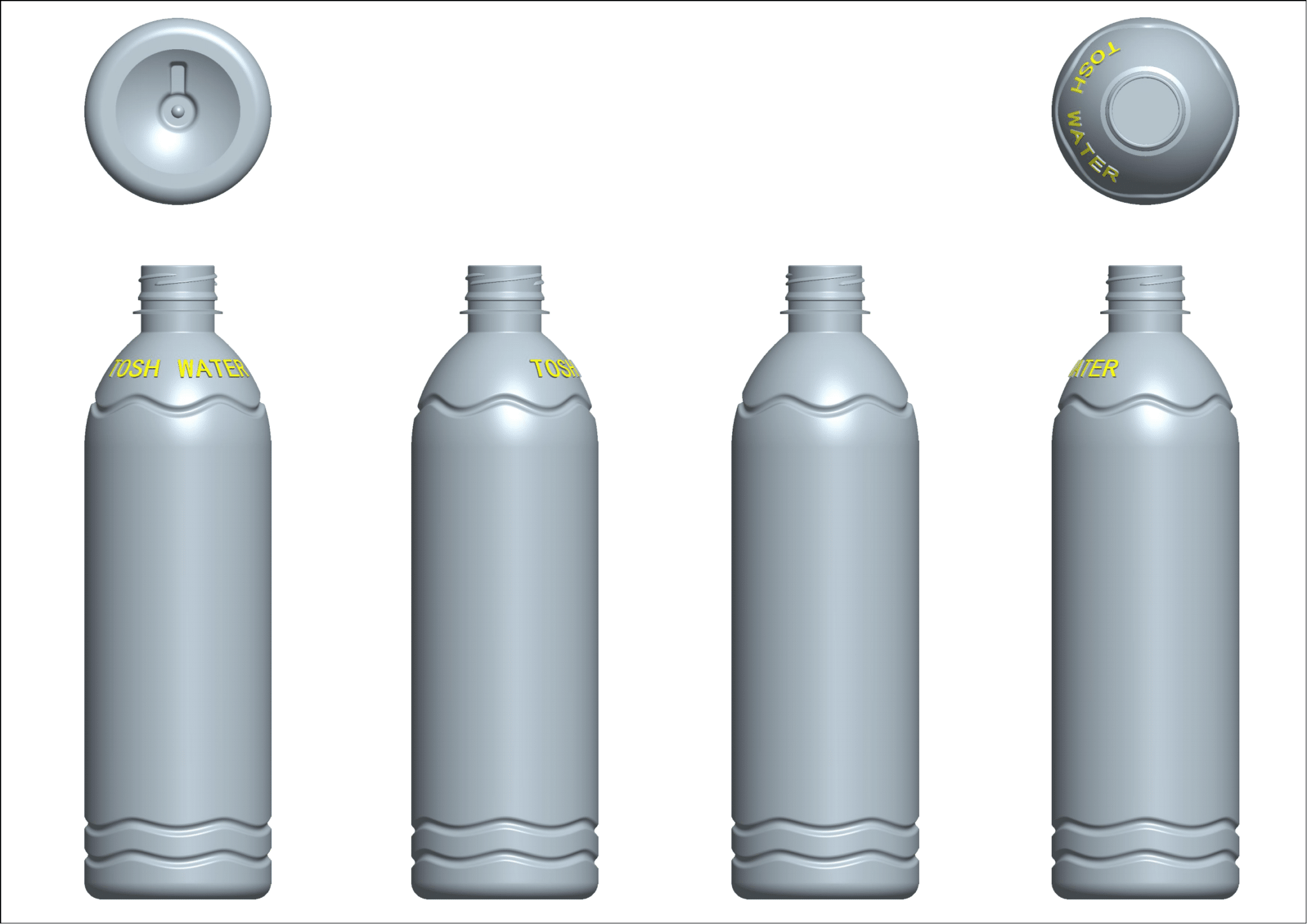

bottle design

Design the bottle you want and save money

According to the product in the bottle, first determine the bottle shape, choose the caliber and grams of the preform, and we will provide some professional suggestions according to your requirements to ensure high yield and low cost. After the design is completed, we will send the renderings and data diagrams of the drawings to you for confirmation.

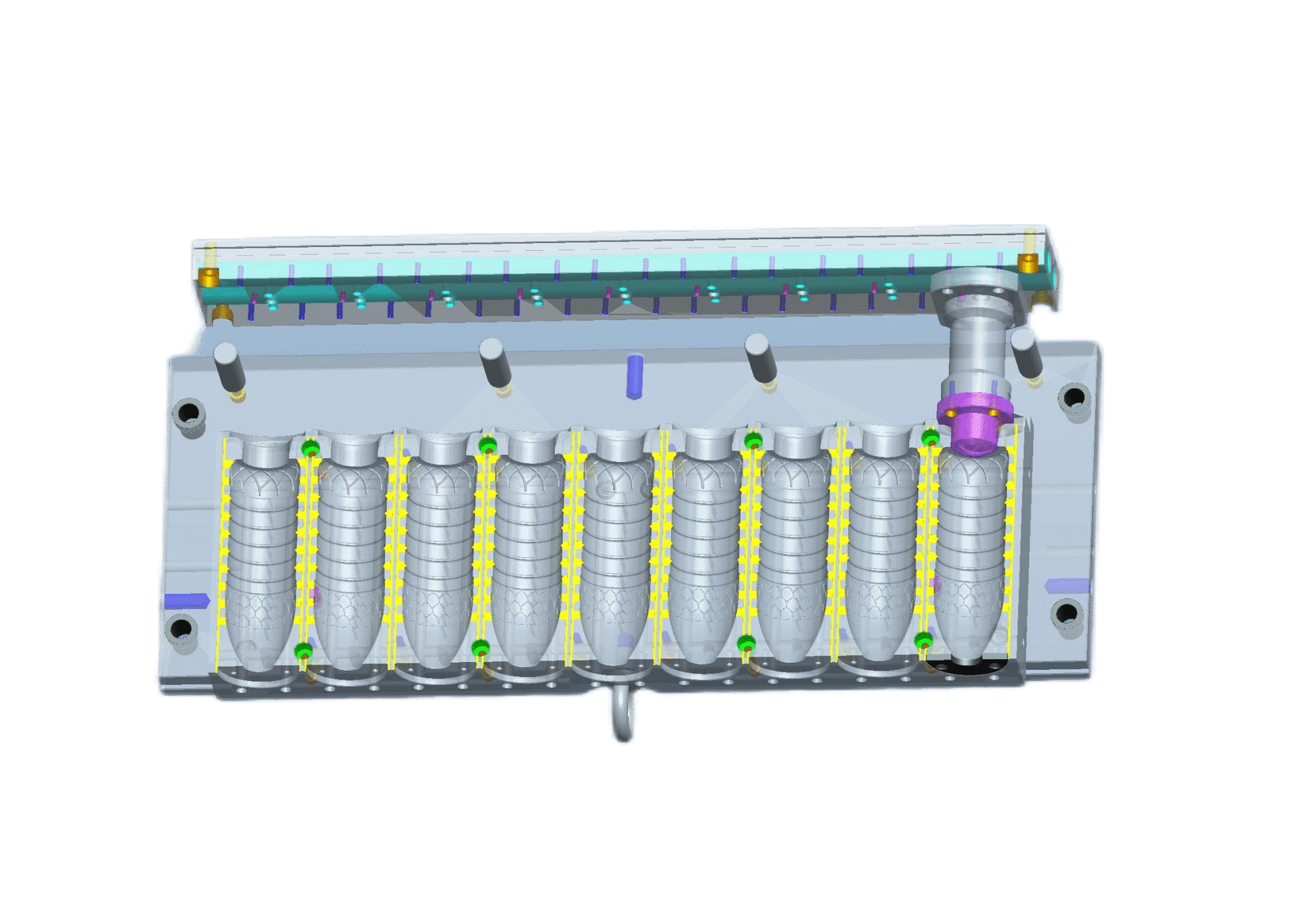

modeling

According to your blow molding machine data

After confirming the bottle design, we need to determine the structure of the mold. Different blow molding machines have different mold structures. We will assist you to complete it and ensure that the data is accurate. The new mold can be installed in your blow molding machine for production.

cNC processing

Guarantee the high precision of the mold

We use CNC milling machines to complete more than 95% of the mold processing to ensure the precision of the mold. The mold is finished and polished so that the mold cavity takes on a mirror finish and the bottle finish is optimal.

Mold assembly

Complete assembly and testing

After the processing is completed, we assemble the mold and conduct inspections, including the consistency of the mold caliber and the preform caliber, the normal operation of the water transport, etc. We will make a sample of some molds and inspect the capacity and height of the bottle.

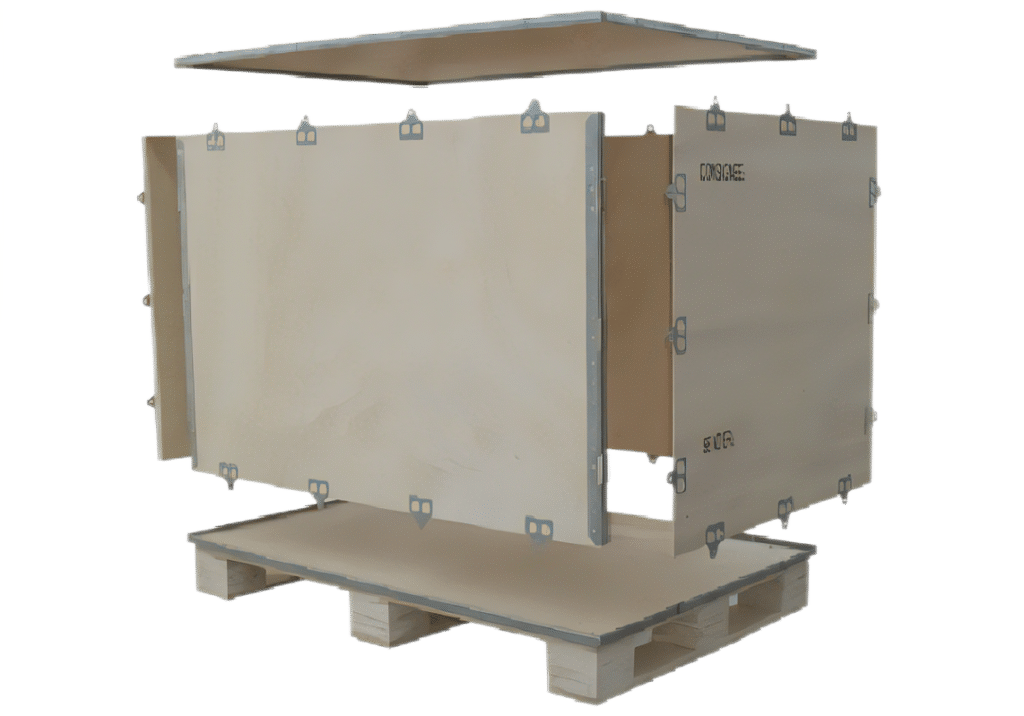

pack and ship

Wooden packing

Most of the molds are packed in wooden boxes, and some molds will be packed according to the selected foam board and carton. All measures are to ensure the safety of mold transportation.

Installation and after-sales

Wooden packing

Most of the molds are packed in wooden boxes, and some molds will be packed according to the selected foam board and carton. All measures are to ensure the safety of mold transportation.

our difference

- One stop solution

Jindong factory has been engaged in the blow molding industry for 20 years. Our main products are bottle blowing machines, blow molds and preform molds. We are one of the earlier factories of PET plastic machinery in China, and we are the designated supplier of famous enterprises in China. We have provided products, solutions and services for 2000+ customers in 20 years. Why we are different from ordinary blow mold factories, because we not only produce blow molds, we also produce blow molding machines, we have more actual blow mold production data than most mold factories, and the molds we design are more Material saving, high bottle yield, strong durability, choose us, not only save your time, but also save your money. Let professional things, please leave it to us, you just need to tell me your needs.

what will you learn ?

At the same time, we can help you solve the problems in bottle blowing, the knowledge of blow molding machine operation, the maintenance and maintenance of molds, and the latest bottle shape trends.

- Blow molding machine knowledge

- Bottle blowing skills

- Blowing solution

- Blowing mold knowledge

- Blow Molding Solutions

- Latest Bottle Trends

you just need:

trust us

contact

request

order

that's what they say

- customer love

I own a mineral water company. We have 3 brands of water, more than 10 types of bottles in total. I asked Vivian to design and manufacture molds for each collection. She will give me some good suggestions, and the quality of the mold is also very good. Of course, when I bought the mold before, I also learned a lot of lessons and spent a lot of money. Vivian is the most satisfactory mold factory I have cooperated with so far.

–Lisa

Mr. Ambrose

Mr.King

There are many bottle blowing mold factories in China, but it is not easy to find a professional and high-quality one. Jindong Mold Factory always surprises me with high-quality molds and good service. I've had the pleasure of getting to know Vivian, she always solves problems.

Gary

I have made more than 100 sets of SIDEL rotary blowing molds in Jindong Company. I was worried when I first cooperated. I made 1 set first. I installed the mold immediately after receiving it. It matches perfectly and works well. , we have cooperated three times.

Debbie

As a buyer, what I am most worried about is the quality of the mold. The price of a set of molds is not high, but a set of molds with poor quality will cost a lot and waste a lot of raw materials, so I am very cautious in purchasing molds. I trust Vivian very much, she is the guarantee of quality.

Co-production with the following machines

bottle blowing machine

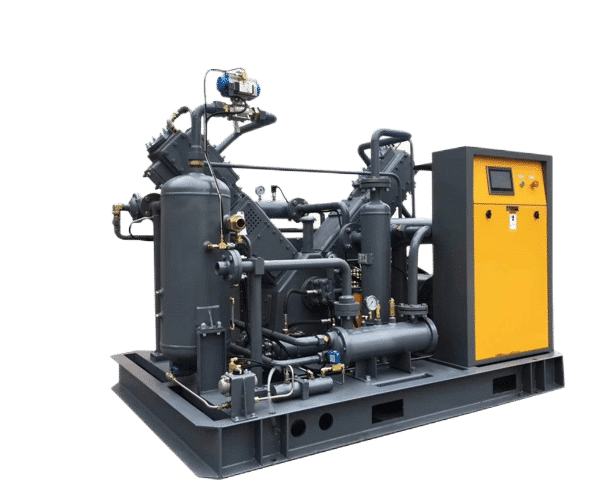

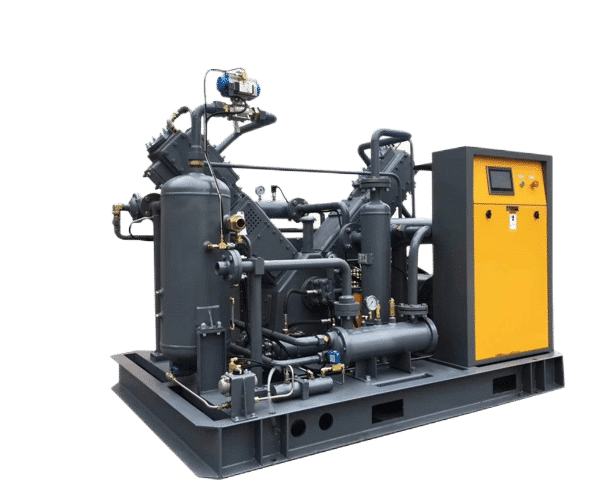

air compressor

chiller

Preform

Co-production with the following machines

bottle blowing machine

air compressor

chiller

Preform

Fill out the form to get the mold price

Take a minute to fill out the form and you can get a free design.

Tell Us What You Need

Try to tell me your requirements, such as the capacity of the bottle, the output you want, or the problem you are encountering now.

Get Solution & Quote

We will provide customized solutions for bottle blowing molds according to your requirements.

custom production

Bottles are designed according to your detailed needs and custom produced.