Outline

1.How to Choose the Right Blowing Mold Manufacturer?

– The Basics of Blowing Mold Industry

– What is a blowing mold?

– Importance of quality in mold production

2.Key Features to Consider when Choosing a Blowing Mold Manufacturer

– Years of industry experience

– The machinery and technology in place

– Detail-oriented product creation

– Post-purchase service and warranty

3.The Benefits of Opting for Experienced Manufacturers

– Ensuring product longevity

– Consistency in mold production

4. Making the Right Choice: A Checklist

– Experience vs. Price: Striking a Balance

– The relevance of having a physical facility

5. Zhongshan Jindong Machinery Co., Ltd: Why We Stand Out?

– Our legacy in the industry

– Our dedicated team and expansive facility

– Our commitment to excellence

6. Conclusion and Takeaways

7. Frequently Asked Questions (FAQs)

—

01.Basic knowledge of blow molding industry

1.What is a PET blow mold?

The process of PET blow molding is: the preform is heated and placed in a PET blow mold, and air is blown into it, forcing the plastic to expand and adapt to the shape of the mould. This results in a strong, perfectly shaped plastic bottle ready to use. The technology is most commonly used to produce PET (polyethylene terephthalate) bottles, which are commonly used in the beverage and other industries due to their light weight, durability and recyclability. The mold involved here is a PET blowing mold, which needs to be combined with blowing machines, air compressors and other equipment to produce together. I have introduced the manufacturing process of PET blowing molds in detail in the previous article. You can refer to More articles of mine.

2.The importance of quality in mold production.

Imagine having a leaking bottle, or one that is prone to breaking. This is what happens when the quality of mold production suffers. PET blow molding molds are more complex than one might first imagine. This is not just to produce hollow plastic objects, but to ensure that each mold produces a consistent, durable and high-quality product, and to control the low scrap rate. The scrap rate cannot be higher than two thousandths, that is, the production of 1000 bottles cannot exceed 2 bottles are scrapped, otherwise the cost of production will be increased. Therefore, high-quality bottle blowing molds not only save labor, but also control costs.

PET blow molds are specially designed to handle PET material. PET is favored by various industries for its clarity, strength, and safety for food and beverages. A well-made PET mold ensures that the PET material retains all its favorable qualities in the final product. It ensures that the bottles produced are free from defects, irregularities and weaknesses.

Ensuring the quality of mold production is not a luxury; it is a necessity. Molds determine the strength, appearance and overall quality of the final product. Therefore, whether you can compromise on inferior molds, compromise will increase your cost. High-quality molds not only guarantee the best possible product, but also save money in the long run due to less waste and higher usage.

—

02. Key features to consider when selecting a blow mold manufacturer

In the field of production, especially when complex processes such as blow molding are involved, the choice of the manufacturer is not only crucial, but also the quality of the final product. Here are some basic features to consider:

1. Years of industry experience

Experience in the field of blow mold making means not only longevity, but also mastery. Manufacturers with years of experience usually mean they have weathered challenges, evolved with technology and perfected their craft over time.

However, it’s not just a problem with the mold itself. Consider this: A craftsman who has spent years making and improving violin bows will have valuable insights into the orchestration of the entire instrument. Likewise, manufacturers with extensive experience in blow molding molds will inevitably have an in-depth understanding of the nuances of the blow molding machines they offer. The two are intertwined in harmony and form a seamless production process.

2. Machinery and technology in place

Modern problems require modern solutions. The intricacies of producing perfect PET bottle molds require not only skilled craftsmanship, but also sophisticated machinery. Machines with higher precision, better calibration and advanced technology integration ensure that every mold produced meets global standards. After all, it is the marriage between man and machine that truly promotes production perfection.

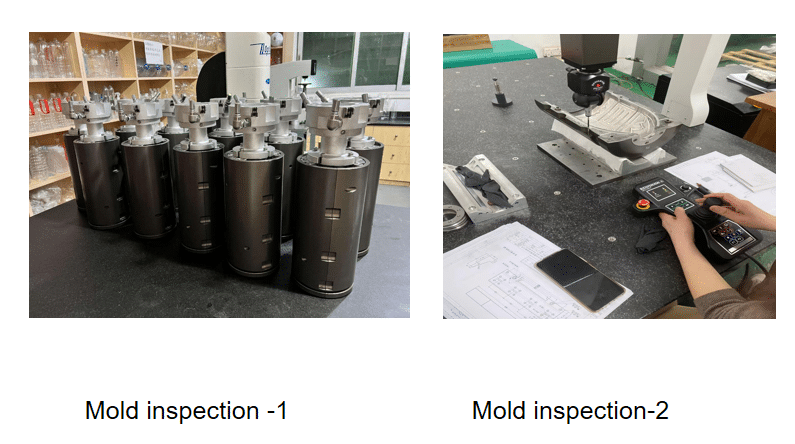

3. Detail-oriented product creation

In the world of blow molding, it’s often the little details that matter the most. From ensuring perfect symmetry to checking for microscopic imperfections, a manufacturer’s attention to detail can make all the difference. A mold may appear perfect to the naked eye, but under inspection by a machine, tiny flaws may be revealed. Choosing a manufacturer who takes these details seriously can ensure the highest quality products.

4. After Sales Service and Warranty

The relationship between manufacturer and customer shouldn’t end with a purchase; it’s just the beginning. A reputable blow mold manufacturer will provide comprehensive after-sales service to ensure that any issues are resolved in a timely manner. Also, a strong warranty is a testament to their confidence in the quality of the product.

It is also worth noting that the synergy between mold and blow molding machine is crucial. Indispensable. Therefore, a manufacturer with extensive experience in both the field of molds and machines is a strong force in ensuring that the entire production chain runs flawlessly. When molds are customized and perfectly synchronized with machinery, the efficiency of the production process is dramatically increased, resulting in unrivaled product quality.

—

03. Benefits of choosing an experienced manufacturer

When we sail in the ocean of industrial production, the experience of manufacturers is often the beacon that guides us to pursue quality. Experience doesn’t just refer to years of working in the industry, but the depth of understanding, adaptability and foresight that those years bring. Here are some of the benefits of working with an experienced blow mold maker:

1. Ensure product life

A seemingly simple bottle, but it is a testimony of precision and quality. A factory with experienced bottle blowing molds, knows the complex changes of materials, temperature and pressure required to make molds, and then creates bottles that can stand the test of time. Just like daily chemical bottles and high-temperature filling bottles, the pressure on the bottles is different. When designing bottles, experienced mold factories must consider these factors in advance. When molds are created with precision and understanding, the final product not only looks good, but lasts longer, maintaining its quality and function.

2.Consistency of mold production

On the production line, consistency is not only a basic requirement. One faulty mold can cause a domino effect, producing thousands of imperfect bottles. One can imagine what a loss this is. After years of repeated tests, an experienced mold factory has simplified the process, high-precision processing equipment, and high-precision testing instruments to ensure the consistency of the mold in each cavity. This consistency translates into reliability every time. product quality.

So an experienced mold shop has the knowledge to anticipate problems before they arise. They are not just suppliers, they are also good partners. They are true partners. They support you, ensuring that every problem has a solution.

—

04. Making the Right Choices: Checklist

Choosing the ideal bottle blowing mold maker is like finding the perfect robot for intelligent solutions. He can not only avoid some mistakes, but also provide you with blow molding knowledge, and help you solve problems in the future production process. With such a high-quality mold factory, this road will become smoother. Here are some considerations:

1. experience and price: strike a balance

A long-standing debate: Do you choose the seasoned veteran or the affordable newcomer? Like many things in life, the answer lies somewhere in the middle.

With experience comes a guarantee of quality, reliability and expertise. An established manufacturer may have encountered and overcome many challenges in the past, honing their skills and perfecting their processes over time. This wealth of knowledge is invaluable in ensuring a smooth production process and a top-notch end product.

However, affordability is a real concern, especially for businesses on tight budgets. While newer or less established manufacturers may offer competitive prices, they may lack the experience and expertise of their seasoned counterparts.

The key here is balance. Consider manufacturers that offer competitive prices without compromising too much on the experience. Keep in mind that the cheapest option isn’t always the best, and the most experienced may not always fit within budget constraints. Assess the potential return on investment and ask yourself: Could saving a little now cost more later in repairs, replacements, or inefficiencies?

In China, everyone knows that Huangyan, Taizhou is a mold base. As early as 10 years ago, as long as foreign customers wanted to buy molds, they wanted to go to Huangyan. But in recent years, everyone has chosen the mold factory in Guangdong. Why? There are too many Lessons from failure. Just like when I met two buyers this year, the first sentence I asked was: where is your factory, we don’t consider Taizhou. I reply every time: My factory is in Guangdong, 20 years of blowing mold factory, 8000 square meters of my own factory.

Therefore, cheap mold prices are not the first choice now, but to choose a balance point between high quality and low price.

2. Dependency with physical facilities

In this digital age, the lure of virtual businesses is real. However, when it comes to tangible products such as blow molds, the importance of physical facilities cannot be overemphasized.

Dedicated processing equipment is not only a testament to the blow mold shop’s commitment and strength, but is also where quality control can be meticulously maintained. Being able to tour, inspect machines, evaluate processes and meet with teams can provide valuable insight into a manufacturer’s operations.

Furthermore, a real location ensures a central point for after-sales service, warranty claims and practical troubleshooting. It provides tangible assurance that there is a place to take responsibility and maintain accountability.

Finding the balance between price and quality can seem daunting, but with in-depth research and a clear understanding of your needs, it’s absolutely achievable. The key is not just to find a manufacturer, but to find a partner, one that aligns with your vision and complements your goals. The right choice not only affects the present, but can also shape the future production trajectory and product quality.

—

05. Zhongshan Jindong Machinery Co., Ltd.: Why do we stand out?

A few entities are dotted on the horizon in the broad landscape of blow mold manufacturing. However, in this vast sea of people, some stars shine even brighter, illuminating the way forward with their brilliance. Zhongshan Jindong Machinery Co., Ltd. is one of them. Here’s what sets us apart:

1. Our Tradition in the Industry

twenty years. That’s when we got our roots in the art and science of blow mold making. These years, we are not just passive participants, but passive participants. We have always been pioneers, leading with innovation, championing quality and setting benchmarks. Our product range is not limited to moulds. We are proud of our range of products including blow molding machines, blow molds and PET preform molds.

But why does this matter? Because when you have hands-on experience producing machinery such as blow molding machines, you gain a deeper understanding of the intricacies of the entire process. This holistic approach gives us an edge. We don’t just make molds; we understand the entire blow molding process, which allows us to have more technical experience and make blow mold manufacturing more suitable for production.

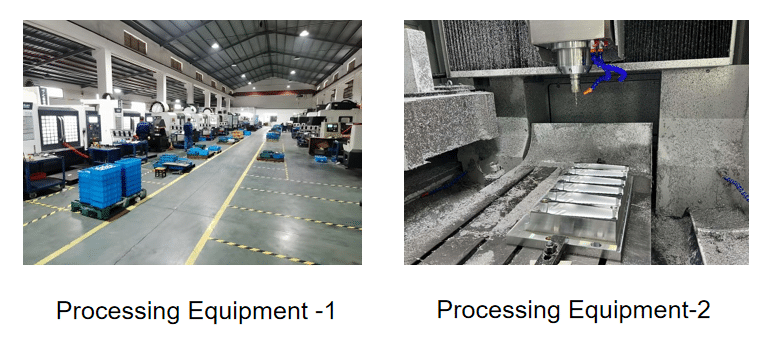

2. Our professional team and spacious facilities

50 dedicated individuals, each contributing their expertise, passion and dedication, form the backbone of our operations. We have 8,000 square meters of factory buildings purchased by ourselves, more than 20 processing equipment, and advanced testing instruments, which are the guarantee of the quality of our bottle blowing molds.

3.Our Commitment to Excellence

Our journey spanning 20 years is a testament not only to our resilience, but also to our unwavering commitment to excellence. We are more than just a mold maker. Given our experience in producing blow molding machines, we have an in-depth knowledge of blow molding technology and a wealth of solutions for potential challenges. This knowledge enables us to proactively innovate solutions and ensure smoother and more efficient production processes for our customers.

Essentially, when you work with Zhongshan Jindong Machinery Co., Ltd., you don’t just get a product; it’s what you get. You are forming a partnership with the legacy. We invite you to be part of our journey and experience the dedication, passion and excellence we bring. Together, let’s build a future that is not only productive but remarkable.

**Visit Now:** [www.vivianmold.com](http://www.vivianmold.com)

—

06. Conclusions and main points

The right partners can make all the difference in industrial manufacturing’s intricate technology. The mold industry has meticulous process requirements and precise processing, so it is necessary to choose a capable and exemplary partner. When you’re selecting the perfect blow mold maker, remember it’s not just about the product, it’s about expertise, commitment and a shared vision.

With a range of options available, a balance between experience and price, an actual factory with dozens of processing equipment, and the reputation of a traditional business like Zhongshan Jindong Machinery Co., Ltd. can be your compass. 20 years in the industry isn’t just a number, it’s a number. It is a testament to reliability, innovation and unwavering quality. As you take the next step, let tradition guide you, quality your constant, and excellence your goal.

—

07. Frequently Asked Questions (FAQ)

**Q1: Why is experience so important in the mold manufacturing industry? **

Answer: Experience translates into expertise. Over time, we developed knowledge of nuances, anticipation of challenges, and innovative solutions. It involves improving processes, honing skills and ensuring consistent quality.

**Question 2: How does the blow molding machine complement the mold making process? **

Answer: Production blow molding machines give you insight into the entire blow molding process. Because the mold is not an independent product, it must be combined with the blow molding machine to produce it, so having more technical experience in the blow molding machine plays a great role in the manufacture of the blow molding mold.

**Question 3: How is Zhongshan Jindong Machinery Co., Ltd. different from other mold manufacturers? **

Answer: In addition to our 20-year heritage, our holistic approach to the blow molding process, including the production of blow molding machines, gives us all-round strengths. We don’t just make molds; we understand the entire process of their production, which is very important in actual production.

**Question 4: How does Zhongshan Jindong Machinery Co., Ltd. ensure after-sales support? **

Answer: Our promise does not end with a sale. With a professional team, spacious facilities and a tradition of excellence, we ensure a quick and efficient resolution to any after-sales requirement, be it repairs or troubleshooting.

—